3D Dry Nano Pulverizer

Nanotechnology is developed from the scale range of 10-9 meter, it has the ability to work at the molecular level to create large structures with fundamentally new molecular organisation. Its interaction by intermolecular and inter-atomic forces will provide the ability to control and manipulate the physical, biological and chemical properties of a system.

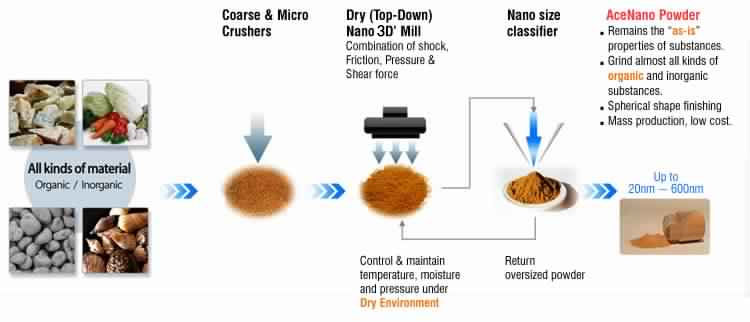

The basis of nanotechnology is the ability to form nano-sized particles. Research has proven that it is possible to mechanically pulverize particles into the nano scale. The key to success is the stabilization of the product suspension against agglomeration and the use of special grinding technique for continuous operation.

The existing Zet Mill/Ball Mill method employs a process that relies on the addition of water or solvent to overcome extreme heat generated during the process. The use of water creates a complication; it poses the risk of oxidizing, and thus sacrificing, the core nutrients, which necessitates a subsequent and inefficient process of re-drying.

Our World’s First 3D Dry Nano Pulverizer has overcome the “Barrier in Nano Powder Technology” which was considered impossible to achieve with existing Zet Mill/Ball Mill method. The 3D Dry Nano Pulveriser adapted the “Ultra Precision Grinding Energy Management System”, which imposes NO HEAT and involves no metallic friction, cutting, or chafing; it does not use water or solvent, and the whole process is executed in a dry environment; temperature, moisture, and pressure levels are completely controlled and monitored. The NO HEAT means that the original integrity of the nutrients is preserved and the non abrasion technology of the metallic devices protects the nutrients from contamination.